Rotary Drilling High Pressure Hose Standard

Pubdate:2023-09-18 16:08 | Hits:

Rotary Drilling High Pressure Hose Standard:(Guide:Introduction→Model→Price→Factory→FAQs)

Rotary Drilling High Pressure Hose Introduction:

The high-pressure hose used in the drilling rig is useful in the pen factory, potassium chlorate factory, meat, sauce product processing plant, lighter factory (metal), noise control equipment factory, etc., involving the production and supply of water industry; Polyester fiber manufacturing; Manufacturing of teaching models and teaching AIDS; Manufacturing of tobacco products; And so many industries. The poor sealing of the inner layer makes the high pressure oil easily enter the wire layer; Adhesive layer and wire layer adhesion is insufficient. Improper selection of the clamping amount and clamping speed during the assembly of the hose and the joint, or unreasonable selection of the structure, material and size of the joint, can lead to too tight or too loose pressure of the hose and the joint, resulting in early damage to the joint. The structure of high pressure steel wire winding hose is mainly composed of inner rubber layer, middle rubber layer, four or multiple layers of alternately winding steel wire reinforcement layer and outer rubber layer. Finally, the vulcanized protective layer is removed, the tube core is drawn out, the upper tube joint is pressed, and the sample pressure inspection is carried out. When the hose is installed, it should avoid being in a tension state, even if there is no relative movement at both ends of the hose, it is necessary to keep the hose loose, and the tensioned hose will expand under pressure and reduce the strength.

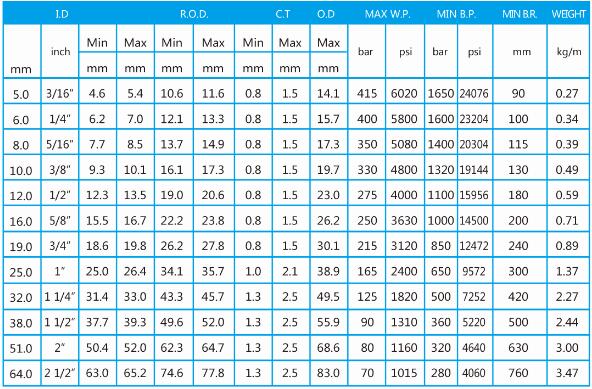

Rotary Drilling High Pressure Hose Model:

Rotary Drilling High Pressure Hose Price:

You can consult Hebei Tengshuo company, we will make a reasonable quotation according to your requirements.

Rotary Drilling High Pressure Hose Factory:

Hebei Tengshuo Rubber Products Co., Ltd. specializes in the production of high pressure hose for drilling rig, high pressure spray hose, foreign trade high pressure hose, injection molding machine high pressure hose, oil high pressure anti-corrosion hose, gas high pressure hose, all kinds, complete supporting parts.

Rotary Drilling High Pressure Hose FAQs:

What is the standard of the hose joint JB1885-77?

National standard A type flat joint core series hose assembly standard. There are several reasons for the leakage of high-pressure hose joints: the leakage caused by the aging or deformation of "dare" ring; The assembly of "Dare" ring is not in place, so that the two planes are connected with uneven pressure or the" dare" ring is cut, resulting in leakage; The "porous" ring is not compacted, and the elastic deformation is insufficient, resulting in leakage. The hole at the end of the "dare-ring" is too deep, resulting in leakage. In this regard, it is necessary to re-select the same outer diameter and thicker section of the "Dare" ring, but also the sealing plane with a groove for cutting or grinding, in order to reduce the depth of the groove, so that the" Dare" ring has enough elastic deformation.

What should you pay attention to when using high and low pressure hose?

When using high and low pressure hose, pay attention to the following: 1. Do not twist the hose during installation. The hose is slightly twisted, which may reduce its strength and loosen the joint, and the joint should be tightened on the hose when assembling, rather than the hose tightened on the joint. 2. When the hose must be bent, the bending radius should not be too small, and should be greater than 9 times the outer diameter. The joint of the hose and the joint shall have a straight line section greater than 2 times the outside diameter of the pipe. 3. The hose layout should avoid heat sources as far as possible and stay away from the performance of the engine exhaust pipe. If necessary, devices such as sleeve or protective screen can be used to prevent the hose from deteriorating due to heat.